All stainless steel materials are made of a superficial layer of chromium oxides, obtained from the chromium of stainless steel and oxygen atmosphere. It is not necessary to put any other type of protection against the corrosion.

If the surface gets damaged, it would be auto-repaired thanks to the oxygen in the atmosphere.

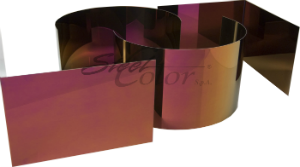

The electro coloring process (INCO) takes advantage of this stainless steel characteristic. The formation of different colors is created by “interference”, actually exploiting the phase difference between the light rays reflected by the several surfaces of oxides (created during the treatment) and the light rays before refracted (by the same oxides) and then reflected again by the surface of the underlying metal.

Main characteristics

Thanks to the increase of the superficial layer of the oxides, the sheets become more resistant

Sheets can be bended and cut without causing any type of alteration

The products resist to UV Rays

Technical characteristics

Thickness: from 0,6 to 3,0 mm

Width: 1250 mm

Length: up to 4000 mmh

*Standard Dimensions: 1250×2500 mm

Available colors

BRONZO – ORO – CHAMPAGNE – BLU – VERDE – ROSSO – VIOLA – GRIGIO – NERO

Available finishes

SUPERMIRROR 8 – MIRROR 7 – SATINATO – SCOTCH BRITE – HAIRLINE – SATINATO INCROCIATO – SATINATO NON DIREZIONALE – PALLINATO